VENFLEX: Visual recognition and mechanical handling of flexible materials

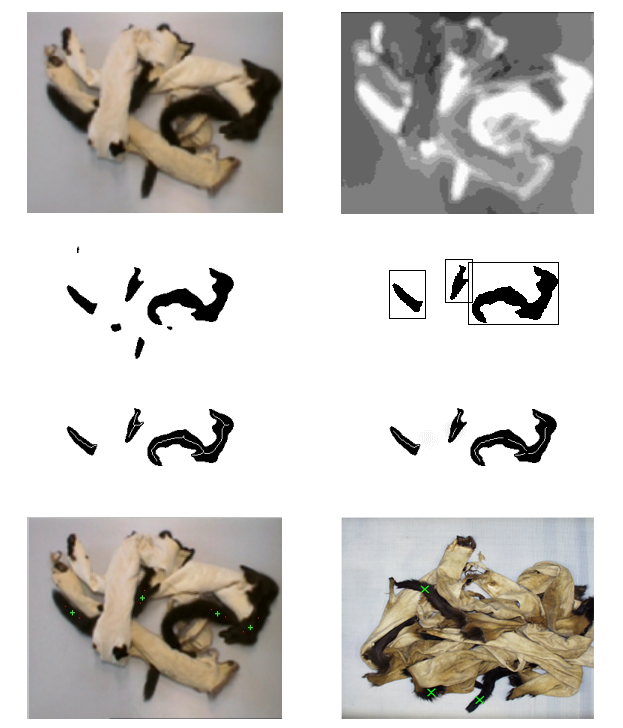

The VENFLEX project refers to the automation of the handling task in the fur tanning industry. Clients of the fur tanning industry are mainly fur garment manufacturers. They supply the fur tanning industry with batches of unprocessed furs (mainly mink furs) which are cleaned and processed in this industry and then delivered back ready for garment assembly. Processes in the fur tanning industry involve fur washing with chemicals and processing of the fur leather so that it becomes clean and subtle. Fur pieces come out of sequentially process stages (washing machines or leather processing stations) in the form of a pell-mell bundle where a high number of furs lie intermingled in bins. Pieces may be either greasy, wet or dry which in turn affects their properties of weight, friction and volume. One of the most frequently encountered tasks, between process stages in these industries, is the placement of these pieces with the same orientation in ordered bundles. This task comes out of the need for faster picking at the next workstation and most importantly the need to avoid permanent piece deformation which occurs if this state is prolonged. Currently, this task is performed manually and accounts for a considerable proportion of the production cycle which will be greatly reduced by its automatization. A fur is a sensitive non homogeneous NRM piece associated with a high value. High grasping forces or tension forces which may arise during the automatic fur manipulation may damage or deform the fur piece. Possible damage or plastic deformation of pieces is translated to a great value loss and is therefore totally unacceptable.

- Category: International Project